PLUS: why should you choose Hydra90

-

Spindle steep taper

BT 40, HSK 63, 50

-

Clamp unit

Special three-point clamp, clamps automatic positioning

-

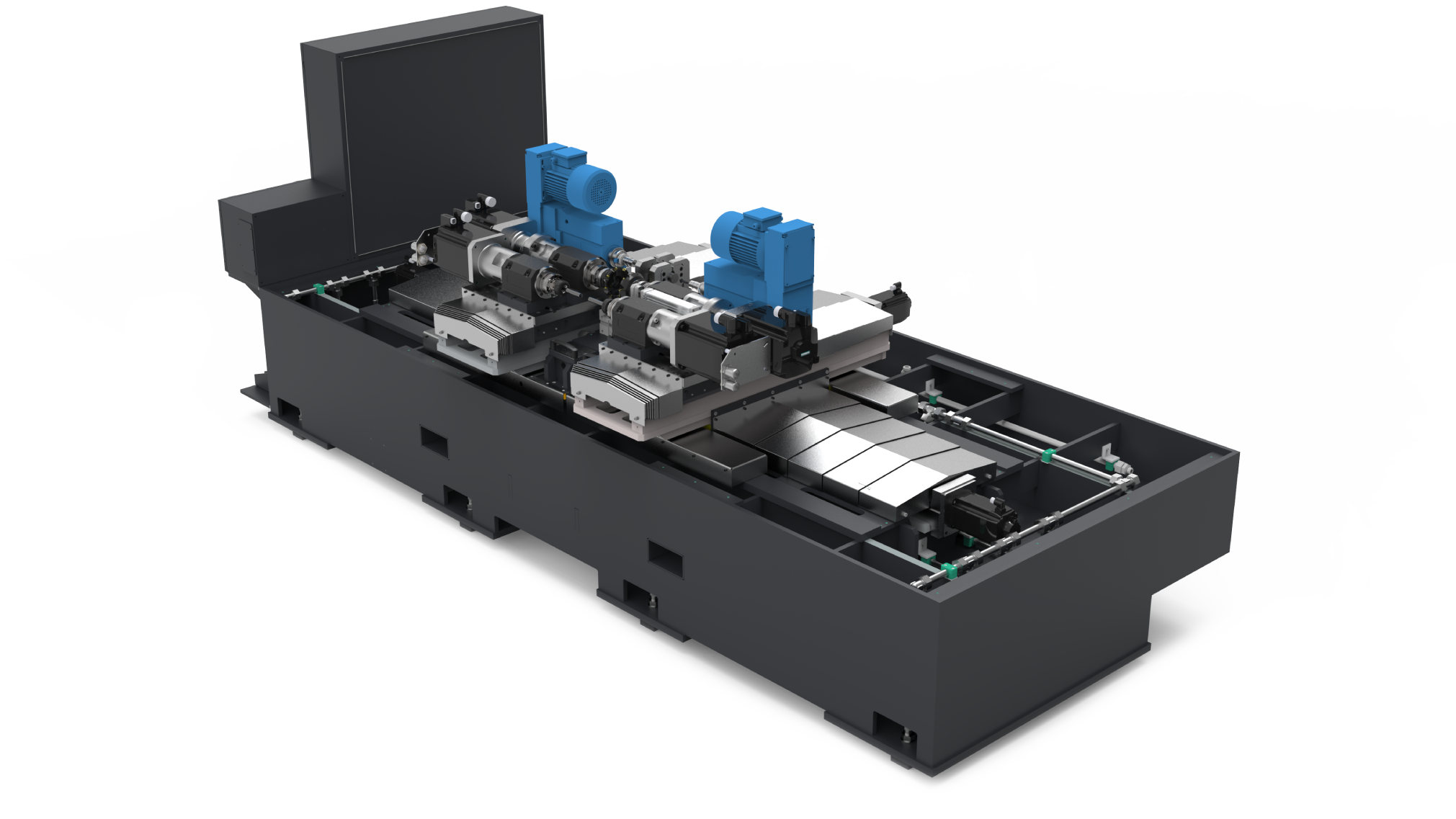

Single/double tapping

Motor power 1,5 Kw

-

Lubrication

Internal lubrication of the tool

-

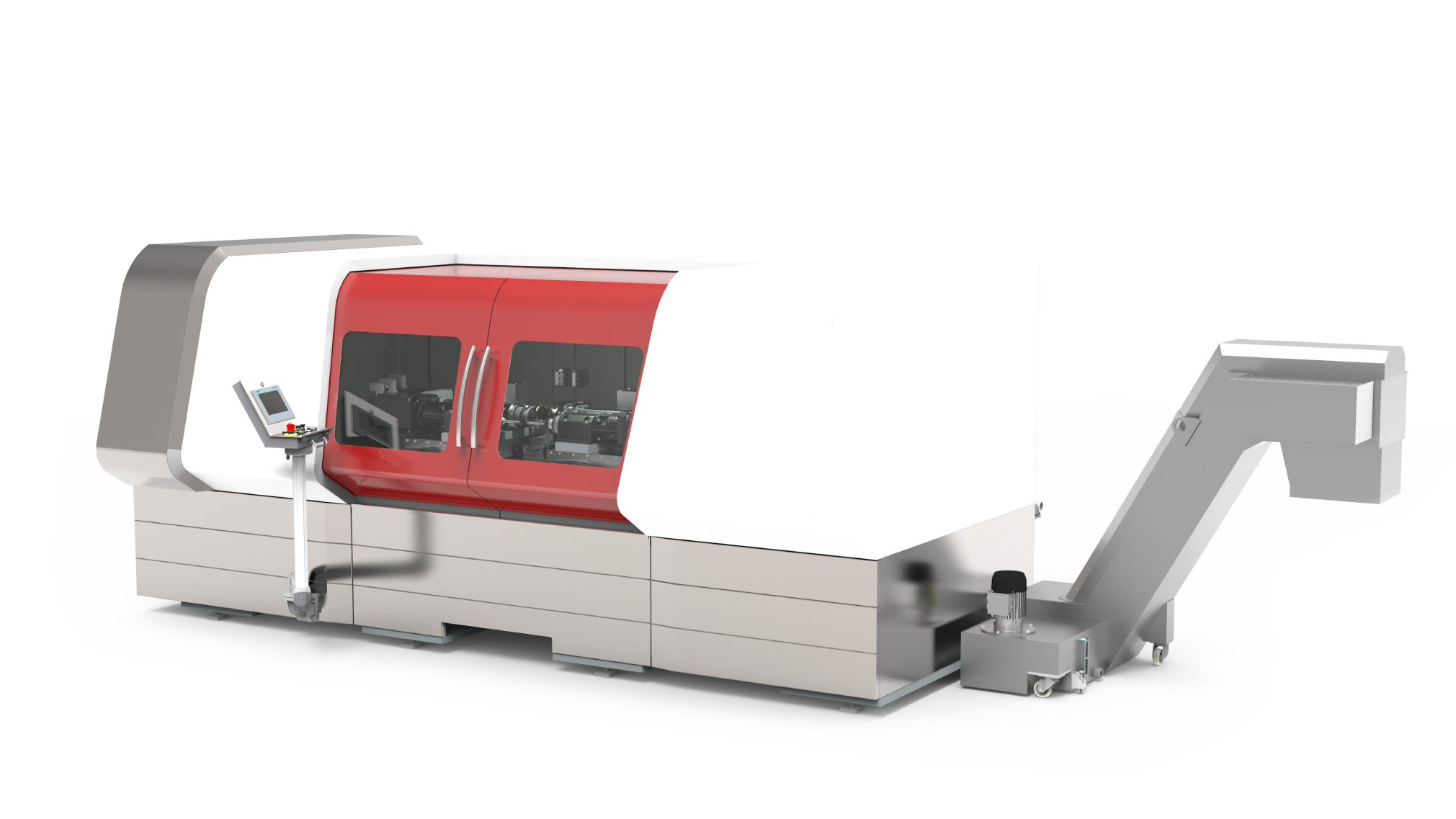

Doors

Automatic opening doors

-

Support

Remote assistance

-

Industry 4.0

4.0 data collection

-

Loading/unloading robot

Six-axes robot for bars loading/unloading