The use of AI for Quality Control in Automotive

Artificial Intelligence is changing the way the automotive industry (and beyond) approaches quality control: a true revolution.

The automotive industry has always been in constant evolution, driven by the goal of producing safer, more efficient, and economically sustainable vehicles. One of the most important challenges is quality control during mass production. This is where artificial intelligence (AI) comes into play, especially in automated assembly lines, revolutionizing how the automotive sector approaches quality control.

Artificial intelligence has become a key resource for improving the precision and efficiency of quality control in automated assembly lines. Its ability to process vast amounts of data in real-time and learn from it enables the detection and prevention of defects with unprecedented accuracy and speed.

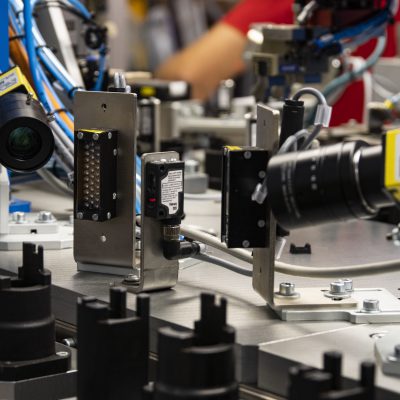

Artificial Vision – The most common application of AI in quality control is artificial vision. Using cameras and advanced sensors, artificial vision systems can inspect specific details such as scratches, dents, paint defects, and misalignment of components. AI analyzes real-time captured images to detect defects, ensuring ever higher quality of assembled components and consequently of the produced vehicles.

Real-Time Data Analysis – AI can collect and analyze real-time data from every part of the production process. This includes data from temperature sensors, pressure sensors, speed sensors, and many other variables. AI compares this data with control parameters and can detect anomalies or significant variations, immediately signaling potential issues to the production chain.

Predictive Maintenance – A crucial aspect of industrial production is machine maintenance. AI can predict the need for preventive maintenance based on the analysis of line data, avoiding costly production interruptions due to sudden breakdowns. This reduces operating costs and improves overall productivity.

Machine Learning – Machine learning is a fundamental branch of AI that allows systems to improve over time. Quality control systems based on machine learning can adapt and improve their defect detection capabilities as they acquire more data and information. This results in greater accuracy and the ability to detect increasingly subtle defects.

The use of AI in quality control in the automotive industry offers a range of significant advantages:

- Quality Improvement: AI minimizes human errors, ensuring greater precision in component production.

- Cost Reduction: AI helps identify and resolve problems more quickly, reducing rework costs and production downtime.

- Increased Production: The ability to detect defects in real-time allows for higher production volumes.

- Safety: By increasing precision in component production, AI can contribute to improving vehicle safety by identifying defects that could compromise it once assembled.

Despite the numerous advantages, the adoption of AI in quality control poses some challenges. Data privacy, interpretation of results, and the impact on employment are all important issues to consider.

Furthermore, it is essential to pay attention to ethics in the use of AI, especially when it comes to safety and accountability issues towards consumers.

Artificial intelligence is revolutionizing quality control in the automotive industry. With its real-time data analysis, defect identification, and machine learning capabilities, AI is improving the quality of produced vehicles, reducing costs, and increasing efficiency. However, it is important to carefully address the ethical and social challenges associated with the adoption of AI to ensure that this technology is used responsibly and safely in the automotive industry and other sectors.